Industry News

-

Comparison of advantages and disadvantages of thin-walled stainless steel pipe connection methods

1. Mutual learning of domestic and foreign stainless steel pipe standards. The internationally common stainless steel pipe connection methods mainly include compression type (convex type), pressing type, push type, welding type (socket argon arc welding type and butt welding t...Read more -

Spiral steel pipe connection methods

Generally speaking, the connection method of spiral steel pipes is welding, because welded pipes are relatively low-cost. Some projects will also use other connection methods such as threads due to construction period, construction conditions, geographical environment, and oth...Read more -

How to solve the deformation problem of spiral submerged arc welded steel pipes

The spiral seam submerged arc welded steel pipe is rotated and drilled and begins to enter the soft formation. Under the action of the three-cone wheel, the drill bit first produces elastic shear deformation of the formation and then is removed under the pressure of the three-...Read more -

Detail of boiler seamless steel tube

Production method of boiler seamless steel pipe: Boiler seamless steel pipe is a type of seamless steel pipe. The manufacturing method is the same as that of seamless steel pipes, but there are strict requirements for the type of steel used in manufacturing steel pipes. Accord...Read more -

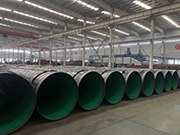

Why 3pe anti-corrosion steel pipes can be anti-corrosion

3PE anti-corrosion steel pipe means a PE steel pipe with three layers of anti-corrosion. 3pe anti-corrosion steel pipe is widely used nowadays, and it is a kind of steel pipe with better anti-corrosion properties. What anti-corrosion materials does the structure of 3pe anti-co...Read more -

How to cool large-diameter steel pipe after the quenching process

Steel pipes are not only used to transport fluids and powdery solids, exchange heat energy, and make mechanical parts and containers, but they are also a kind of economical steel. Using steel pipes to make building structural grids, pillars, and mechanical supports can reduce ...Read more -

How is the spiral seam submerged arc welded steel pipe anti-corrosion

1. Mainly use tools such as wire brushes to polish the steel surface. Cleaning and preheating the spiral welded pipe can remove loose or lifted scales, rust, welding slag, etc. The rust removal of hand tools can reach the Sa2 level, and the rust removal of power tools can reac...Read more -

Precautions when welding spiral steel pipe

It is inevitable to weld and cut the spiral steel pipe structure in the application of spiral steel pipe. Due to the characteristics of the spiral steel pipe itself, the welding and cutting of the spiral steel pipe has its particularities compared with ordinary carbon steel. I...Read more -

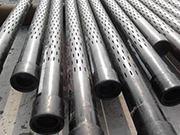

Features of oil slotted pipe

1. The oil slotted pipe is processed by a J55 or N80 oil casing body, which has high strength and is not easy to deform 2. The verticality of the cutting edge is good, the cutting edge is smooth, no burr, and the cutting seam is even. 3. Large flow area, the 27/8″ slotte...Read more