ASTM A333 Tube

What is ASTM A333 steel pipe?

ASTM A333 steel pipe is the standard specification for seamless and welded carbon and alloy steel pipe for low-temperature service or other applications requiring notch toughness. There are several grades of ferritic steel covered by this standard: Grade, Grade 3, Grade 4, Grade 6, Grade 7, Grade 8, Grade 9, Grade 10, and Grade 11. Metals-Piping provides ASTM A333 steel pipes made by the seamless or welded process with the addition of no filler metal in the welding operation except that Grade 4 shall be made only by seamless process. The pipe shall be furnished free of welding repair, either radiographically tested or ultrasonically examined.

Download

ASTM A333 Steel Pipe Chemical Composition Requirements

|

Chemical Composition of ASTM A333 |

|||||||||

|

Element |

Grade 1, % |

Grade 3, % |

Grade 4, % |

Grade 6, % |

Grade 7, % |

Grade 8, % |

Grade 9, % |

Grade 10, % |

Grade 11, % |

|

C |

0.30 |

0.19 |

0.12 |

0.30 |

0.19 |

0.13 |

0.20 |

0.20 |

0.10 |

|

Mn |

0.40–1.06 |

0.31–0.64 |

0.50–1.05 |

0.29–1.06 |

0.90 |

0.90 |

0.40–1.06 |

1.15–1.50 |

0.60 |

|

P |

0.025 |

0.025 |

0.025 |

0.025 |

0.025 |

0.025 |

0.025 |

0.035 |

0.025 |

|

S |

0.025 |

0.025 |

0.025 |

0.025 |

0.025 |

0.025 |

0.025 |

0.015 |

0.025 |

|

Si |

... |

0.18–0.37 |

0.08–0.37 |

0.10 min |

0.13–0.32 |

0.13–0.32 |

... |

0.10–0.35 |

0.35 |

|

Ni |

... |

3.18–3.82 |

0.47–0.98 |

0.40 |

2.03–2.57 |

8.40–9.60 |

1.60–2.24 |

0.25 |

35.0–37.0 |

|

Cr |

... |

... |

0.44–1.01 |

0.30 |

... |

... |

... |

0.15 |

0.50 |

|

Cu |

... |

... |

0.40–0.75 |

0.40 |

... |

... |

0.75–1.25 |

0.15 |

... |

|

Al |

... |

... |

0.04–0.30 |

... |

... |

... |

... |

0.06 |

... |

|

V |

... |

... |

... |

0.08 |

... |

... |

... |

0.12 |

... |

|

Cb |

... |

... |

... |

0.02 |

... |

... |

... |

0.05 |

... |

|

Mo |

... |

... |

... |

0.12 |

... |

... |

... |

0.05 |

0.50 |

|

Co |

... |

... |

... |

... |

... |

... |

... |

... |

0.50 |

*For Grade 1 and 6, each reduction of 0.01% C below 0.30%, an increase of 0.05 % Mn above 1.06 % would be permitted to a max. of 1.35%.

*For Grade 6, the limit for columbium may be increased up to 0.05 % on heat analysis and 0.06 % on product analysis.

*Generally, the carbon equivalent C.E = [C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15] shall not exceed 0.43% by heat analysis.

ASTM A333 Steel Pipe Mechanical Properties

|

ASTM A333 |

Tensile Strength, min. |

Yield Strength, min. |

Elongation %, min. |

|||

|

Grade |

psi |

MPa |

psi |

MPa |

Longitudinal |

Transverse |

|

Grade 1 |

55 000 |

380 |

30 000 |

205 |

35 |

25 |

|

Grade 3 |

65 000 |

450 |

35 000 |

240 |

30 |

20 |

|

Grade 4 |

60 000 |

415 |

35 000 |

240 |

30 |

16.5 |

|

Grade 6 |

60 000 |

415 |

35 000 |

240 |

30 |

16.5 |

|

Grade 7 |

65 000 |

450 |

35 000 |

240 |

30 |

22 |

|

Grade 8 |

100 000 |

690 |

75 000 |

515 |

22 |

... |

|

Grade 9 |

63 000 |

435 |

46 000 |

315 |

28 |

... |

|

Grade 10 |

80 000 |

550 |

65 000 |

450 |

22 |

... |

|

Grade 11 |

65 000 |

450 |

35 000 |

240 |

18 |

... |

*The elongation values are furnished on the basis of standard round 2 inch or 50 mm(or 4D) specimens.

*Elongation of Grade 11 is for all walls and small sizes tested in full section.

Charpy V-notch Impact Tests of ASTM A333 Steel Pipe

|

Impact Requirements for Grades 1, 3, 4, 6, 7, 9, 10, and 11 |

||||

|

Size of Specimen |

*A |

*B |

||

|

mm |

ft·lbf |

J |

ft·lbf |

J |

|

10 by 10 |

13 |

18 |

10 |

14 |

|

10 by 7.5 |

10 |

14 |

8 |

11 |

|

10 by 6.67 |

9 |

12 |

7 |

9 |

|

10 by 5 |

7 |

9 |

5 |

7 |

|

10 by 3.33 |

5 |

7 |

3 |

4 |

|

10 by 2.5 |

4 |

5 |

3 |

4 |

*A denotes minimum average notched bar impact value of each set of three specimens.

*B denotes minimum notched bar impact value of one specimen only of a set.

|

Minimum Impact Test Temperature of ASTM A333 |

||

|

Grade |

°F |

°C |

|

1 |

-50 |

-45 |

|

3 |

-150 |

-100 |

|

4 |

-150 |

-100 |

|

6 |

-50 |

-45 |

|

7 |

-100 |

-75 |

|

8 |

-320 |

-195 |

|

9 |

-100 |

-75 |

|

10 |

-75 |

-60 |

|

11 |

-320 |

-195 |

* Impact tests specified for temperatures lower than 70 °F [20 °C] should be made with precautions.

All seamless and welded pipes manufactured to ASTM A333, other than Grades 8 and 11, shall be heat treated to control their microstructure in accordance with one of the following methods:

Normalize by heating to a uniform temperature of not less than 1500 °F [815 °C] and cool in air or in the cooling chamber of an atmosphere controlled furnace. Or normalize as above-mentioned, and, at the discretion of the manufacturer, reheat to a suitable tempering temperature.

For the seamless process only, reheat and control hot working and the temperature of the hot-finishing operation to a finishing temperature range from 1550 to 1750 °F [845 to 945 °C] and cool in air or in a controlled atmosphere furnace from an initial temperature of not less than 1550 °F [845 °C]. Or treat as above-mentioned, and, at the discretion of the manufacturer, reheat to a suitable tempering temperature.

Seamless pipe of Grades 1, 6, and 10 may be heat treated by heating to a uniform temperature of not less than 1500 °F [815 °C], followed by quenching in liquid and reheating to a suitable tempering temperature.

ASTM A333 Grade 8 pipe shall be heat treated by the manufacturer by either of the following methods: quenched + tempered; double normalized + tempered. When required, Grade 11 shall be annealed and then normalized in the range of 1400 to 1600 °F [760 to 870 °C].

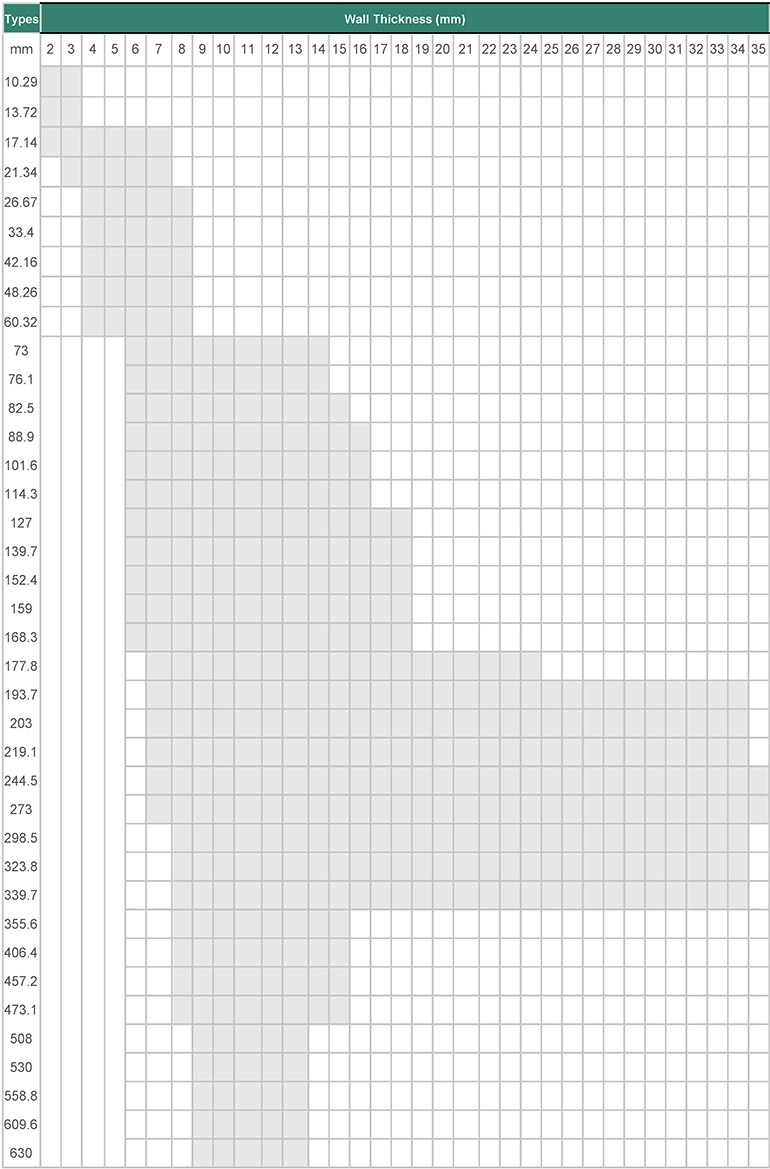

Size Chart of ASTM A333 Steel Pipe

Application of ASTM A333 Steel Pipe

- LNG Low-temperature pipeline

- low-temperature equipment

- Fire-tube boiler

- Water-tube boiler

- Shipbuilding

- Construction

- Chemical

- Petrochemical

- Food processing

- Oil and gas and other industrial applications

We are a professional Boiler And Alloy Tube manufacturer. We provide Boiler And Alloy Tube of different sizes as well as steel pipes and pipe fittings of various specifications.

Our Advantages:

1.China-leading product service provider and exporter of steel pipe

2.Competitive price and quality from our own factory

3.One-stop Resource Integration

4.Passed the ISO9001, CE, SGS certification every year

5.Best service with 24-hour response

6.Flexible payment methods

7.Strong production capacity

8.Fast delivery and standard export packaging

9.OEM/ODM

If you would like to inquire about any steel products, please feel free to contact us:sales@bestartubes.com