BS1387 Pipe

What is BS1387 steel pipe?

BS1387 steel pipe is a British standard for black welded pipes for BS21 tanks and BS21 tanks. BS 1387 hot-dip galvanized steel tubes are used for gas, air, and water transport, civil, and other structures. BS1387 galvanized pipe with nominal size DN8-DN150 in light, medium, and heavy thickness.

BS1387 galvanized steel pipe, also known as GI steel pipe, can classified into two kinds. One is a hot-dipped galvanized steel pipe, the other is an electric steel pipe. The advantage of hot-dipped galvanized steel pipe is that the galvanized coating will be thicker, and the zinc coating will be fairly and can stick to the pipe body better. And life span of hot dipped galvanized steel pipe is longer.

BS1387 Steel Pipe Advantage

Being a quality-focused BS1387 pipe manufacturer, we provide BS1387 steel tubes strictly using high-grade material. Our BS1387 galvanized pipes are worldwide used in the piping systems of oil, gas, chemical, food processing, and petrochemical industries. We are always adhering to our missions of producing high-quality BS1387 steel pipes and good service. Here are some advantages of BS1387 galvanized iron pipe you can take as a reference in terms of selecting pleasing and suited BS1387 black steel pipes.

High Efficiency: A variety of BS1387 steel pipes are provided for the high demand for these parts to construct buildings. To improve the deep integration of the new generation of information technology and BS1387 steel pipe applications, we aim for high-quality products.

Enhanced Strength and Durability: With an urgent demand, the BS1387 steel tube can make the building parts strong and durable for a long period. Since the BS1387 steel pipe has greater structural strength, the users of the BS1387 galvanized iron pipe have long-term satisfaction with our BS1387 steel pipe.

Strict Quality Control: BS1387 galvanized steel pipes are acceptable for inspection from a third party appointed or paid by the buyer, such as SGS, or BV.

BS1387 Steel Pipe End Finish and End Protection

Plain-end square-cut (PE) or threaded and fixed with coupling (T/C). (PE) tubes are shipped without any protection on both ends. T/C tubes are supplied screwed with taper threads to BS 21 and fitted with one taper-threaded malleable iron socket, as required under this specifications.

BS1387 Steel Pipe Specification

| Chemical Composition | C max | Mn Max | P Max | S Max |

| 0.20% | 1.20% | 0.045% | 0.045% | |

| Mechanical Properties | Tensile Strength (N/mm2) | 320-460 | ||

| Yield Strength (N/MM2) | 195 min | |||

| Elogation | 20 min | |||

| Tolerances on Dimensions and Mass | Wall Thickness of Light tubes | -8% | ||

| Wall thickness of Medium and Heavy Tubes | -10% | |||

| Mass | The mean consign mass for quantities of 150m and over of one size shall not devite by more than ±4% from the mass of consignment calculated from the mass given in table as appropriate. No single tube shall deviate by more than +10%, -8% from the mass given in table as appropriate. | |||

| Hop-Dip Zinc Coating Test (if required) | After the four successive one-minute immersions in the copper-sulphate solutiuon, the test sample shall not show any adherent red deposite of metallic copper. | |||

| Bend Test | Black tubes up to and including DN 50 shall be bent cold without any signs of fracture or failure, through 180℃ round a former having a radius at the bottom of the groove equal to six times the outside diameter of the tube as given in Table. Hot-dip-zinc coated tubes shall be bent cold with out cracking of the steel, through 90°round a former having a radius at the bottom of the groove equal to eight times the outside diameter of tube. | |||

| Flattening Test | The flattening test applies to tubes greater than DN50.

A ring not less than 40mm in length taken from one end of each selected tube shall be flattened cold between parallel flat platens without showing either crack or flaw until the distance between the platens, meaasured under load, is not greater than 75% of original outside diameter of the tube, and no cracks or flaws in the metal elsewhere than in the weld shall occur until the distance between the platens is less than 60% of original diameter. The weld shall be placed at 90°to the direction of flattening. |

|||

| Leak Tightness Test | The test shall be either a hydraulic test at a pressure of 50 bar (50×105 N/M²), or alternatively, an eddy current test. | |||

| Bore Test for Hop-Dip Coated Tubes | Hot-dip zinc coated tubes up to and including DN25 shall have a rod 230mm in length, of the appropriate diameter specified below, passed through them and shall have a free bore. | |||

BS1387 Steel Pipe Size

| Class | Nominal Diameter (DN) mm | Designation of thread Inch | Outside diameter | Thickness mm | Mass of black tube | ||

| Max mm | Min mm | Plain end kg/m | Screwed and socketed kg/m | ||||

| Light | 15 | 1/2 | 21.4 | 21.0 | 2.0 | 0.947 | 0.956 |

| 20 | 3/4 | 26.9 | 26.4 | 2.3 | 1.38 | 1.39 | |

| 25 | 1 | 33.8 | 33.2 | 2.6 | 1.98 | 2.00 | |

| 32 | 1 1/4 | 42.5 | 41 .9 | 2.6 | 2.54 | 2.57 | |

| 40 50 | 1 1/2 2 | 48.4 60.2 | 47.8 59.60 | 2.9 2.9 | 3.23 4.08 | 3.27 4.15 | |

| 65 | 2 1/2 | 76.0 | 75.2 | 3.2 | 5.71 | 5.83 | |

| 80 | 3 | 88.7 | 87.9 | 3.2 | 6.72 | 6.89 | |

| 100 | 4 | 113.9 | 113.0 | 3.6 | 9.75 | 10.0 | |

| Medium | 15 | 1/2 | 21.7 | 21.1 | 2.6 | 1.21 | 1.22 |

| 20 | 3/4 | 27.2 | 26.6 | 2.6 | 1.56 | 1.57 | |

| 25 | 1 | 34.2 | 33.4 | 3.2 | 2.41 | 2.43 | |

| 32 | 1 1/4 | 42.9 | 42.1 | 3.2 | 3.10 | 3.13 | |

| 40 | 1 1/2 | 48.4 | 48.0 | 3.2 | 3.57 | 3.61 | |

| 50 | 2 | 60.8 | 59.8 | 3.6 | 5.03 | 5.10 | |

| 65 | 2 1/2 | 76.6 | 75.4 | 3.6 | 6.43 | 6.55 | |

| 80 | 3 | 89.5 | 88.1 | 4.0 | 8.37 | 8.54 | |

| 100 | 4 | 114.9 | 113.3 | 4.5 | 12.2 | 12.5 | |

| 125 | 5 | 140.6 | 138.7 | 5.0 | 16.6 | 17.1 | |

| 150 | 6 | 166.1 | 164.1 | 5.0 | 19.7 | 20.3 | |

| Heavy | 15 | 1/2 | 21.7 | 21.1 | 3.2 | 1.44 | 1.45 |

| 20 | 3/4 | 27.2 | 26.6 | 3.2 | 1.87 | 1.88 | |

| 25 | 1 | 34.2 | 33.4 | 4.0 | 2.94 | 2.96 | |

| 32 | 1 1/4 | 42.9 | 42.1 | 4.0 | 3.80 | 3.83 | |

| 40 | 1 1/2 | 48.8 | 48.0 | 4.0 | 4.38 | 4.42 | |

| 50 | 2 | 60.8 | 59.8 | 4.5 | 6.19 | 6.26 | |

| 65 | 2 1/2 | 76.6 | 75.4 | 4.5 | 7.93 | 8.05 | |

| 80 | 3 | 89.5 | 88.1 | 5.0 | 10.3 | 10.5 | |

| 100 | 4 | 114.9 | 113.3 | 5.4 | 14.5 | 14.8 | |

| 125 | 5 | 140.6 | 138.7 | 5.4 | 17.9 | 18.4 | |

| 150 | 6 | 166.1 | 164.1 | 5.4 | 21.3 | 21.9 | |

| NOTES: 1) Dimensions and masses are accordance with ISO R65 2) Hydrostatic test pressure 50 kg/cm2 |

|||||||

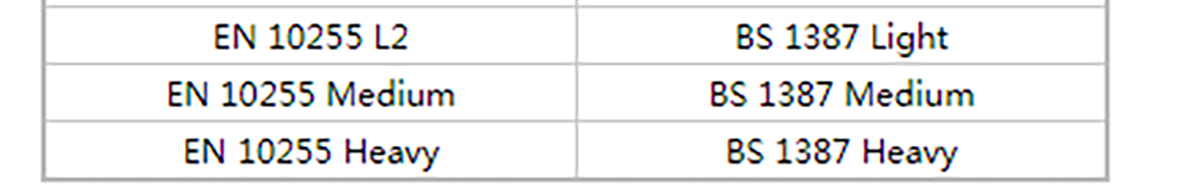

BS1387 Steel Pipe Table

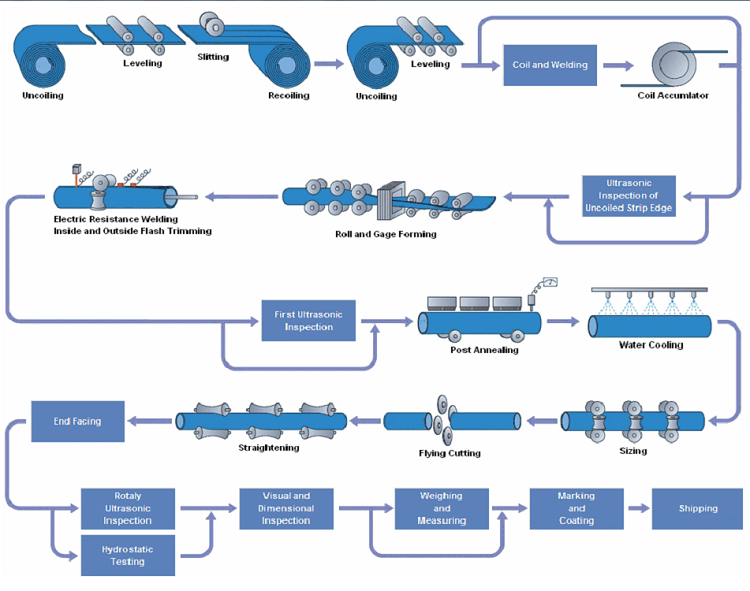

Manufacturing Process of BS1387 Steel Pipe

Application of BS1387 Steel Pipe

- Ordinary conveyance transport

- Steam transport

- Gas transport

- Air transport

- Water transport

We are a professional Carbon Steel Pipe manufacturer. We provide Carbon Steel Pipe of different sizes as well as steel pipes and pipe fittings of various specifications.

Our Advantages:

1.China-leading product service provider and exporter of steel pipe

2.Competitive price and quality from our own factory

3.One-stop Resource Integration

4.Passed the ISO9001, CE, SGS certification every year

5.Best service with 24-hour response

6.Flexible payment methods

7.Strong production capacity

8.Fast delivery and standard export packaging

9.OEM/ODM

If you would like to inquire about any steel products, please feel free to contact us:sales@bestartubes.com