EN 10216-2 Tube

What is EN10216-2 Steel Pipe?

EN10216-2 steel pipe is specification made for seamless steel tubes for specified elevated temperature purposes such as boiler tubes, power plants, etc, it has the following steel grades: P195GH, P235GH, P265GH, 16Mo3, 14MoV6-3, 13CrMo4-5, 10CrMo9-10, with non-alloy and alloy steel included. EN 10216-2 steel pipe specifies the technical delivery conditions in 2 test categories for seamless tubes of circular cross-section, Bestar Steel is an experienced boiler and pressure steel tube supplier that can offer you EN10216-2 steel tubes of all grade and dimension ranges.

EN 10216-2 Steel Pipe Chemical Composition

| Steel grades | EN10216-2 Steel Pipe CHEMICAL COMPOSITION (LADLE ANALYSIS) | |||||||

| C% max | Si% max | Mn% max | P% max | S% max | Cr% max | Mo% max | Ni% max | |

| P195GH | 0.13 | 0.35 | 0.7 | 0.025 | 0.02 | 0.3 | 0.08 | 0.3 |

| P235GH | 0.16 | 0.35 | 1,20 | 0.025 | 0.02 | 0.3 | 0.08 | 0.3 |

| P265GH | 0.2 | 0.4 | 1,40 | 0.025 | 0.02 | 0.3 | 0.08 | 0.3 |

| 16Mo3 | 0.12- 0.20 | 0.35 | 0.40- 0.70 | 0.025 | 0.02 | 0.3 | 0.25- 0.35 | 0.3 |

| 14MoV6-3 | 0.10- 0.15 | 0.15- 0.35 | 0.40- 0.70 | 0.025 | 0.02 | 0.30- 0.60 | 0.50- 0.70 | 0.3 |

| 13CrMo4-5 | 0.15 | 0.50- 1,00 | 0.30- 0.60 | 0.025 | 0.02 | 1,00- 1,50 | 0.45- 0.65 | 0.3 |

| 10CrMo9-10 | 0.10- 0.17 | 0.35 | 0.40- 0.70 | 0.025 | 0.02 | 0.70- 1,15 | 0.40- 0.60 | 0.3 |

EN 10216-2 Steel Pipe Mechanical Property

| EN 10216-2 Steel Pipe Mechanical properties | ||||||||||||

| Steel grades | Mechanical properties during tensile testing at room temperature | Resilience | ||||||||||

| Upper yield limit or yield strength Re or R0.2 for wall thickness of t min | Tensile strength Rm | Elongation A min% | Minimum energy average absorbed KVJ at the temperature of 0°C | |||||||||

| T≤16 | 16<T≤40 | 40<t≤60 | 60<T≤60 | I | T | |||||||

| MPa | MPa | MPa | MPa | MPa | I | t | 20 | 0 | -10 | 20 | 0 | |

| P195GH | 195 | - | - | - | 320- 440 | 27 | 25 | - | 40 | 28 | - | 27 |

| P235GH | 235 | 225 | 215 | - | 360- 500 | 25 | 23 | - | 40 | 28 | - | 27 |

| P265GH | 265 | 255 | 245 | - | 410- 570 | 23 | 21 | - | 40 | 28 | - | 27 |

| 16Mo3 | 280 | 270 | 260 | - | 450- 600 | 22 | 20 | 40 | - | - | 27 | - |

| 14MoV6-3 | 320 | 320 | 310 | - | 460- 610 | 20 | 18 | 40 | - | - | 27 | - |

| 13CrMo4-5 | 290 | 290 | 280 | - | 440- 590 | 22 | 20 | 40 | - | - | 27 | - |

| 10CrMo9-10 | 280 | 280 | 270 | - | 480- 630 | 22 | 20 | 40 | - | - | 27 | - |

EN 10216-2 Steel Pipe Equivalent steel grade

| Steel Grade | Steel Standard | Steel Grade | Steel Standard | Steel Grade |

| P235GH | DIN 17175 | St 35.8 | ||

| P265GH | DIN 17175 | St 45.8 | ||

| 16Mo3 | DIN 17175 | 15Mo3 | ||

| 10CrMo55 | 15Mo3 | BS 3606 | 621 | |

| 13CrMo45 | DIN 17175 | BS 3606 | 620 | |

| 10CrMo910 | DIN 17175 | 13CrMo44 | BS 3606 | 622 |

| 25CrMo4 | 10CrMo910 | |||

| P355N | DIN 17179 | StE 355 | ||

| P355NH | DIN 17179 | TStE 355 | ||

| P355NL1 | DIN 17179 | WStE 460 | ||

| P460N | DIN 17179 | TStE 460 | ||

| P460NH | DIN 17179 | WStE 460 | ||

| P460NL1 | DIN 17179 | TStE 460 |

Dimension for EN10216-2 Steel pipe

| EN 10216-2 Steel Pipe Outside diameter and wall thickness tolerances | |||||

| Outside diameter D mm | Permissible deviations of outside diameter D | Permissible deviations of wall thickness t depending on the T/D ratio | |||

| ≤0.025 | >0.025 ≤0.050 |

>0.050 ≤0.10 |

>0.10 | ||

| D≤219,1 | +\- 1% or =\- 0.5mm depending on which is greater | +\- 12,5% or 0.4 mm depending on which is greater | |||

| D>219,1 | =\- 20% | =\- 15% | =\- 12,5% | =\- 10% | |

| For the outside diameter of D≥355,6 mm, local deviation outside of the upper deviation limit by a further 5% of the wall thickness T is permitted | |||||

| EN 10216-2 Steel Pipe Inside diameter and wall thickness tolerances | |||||

| Permissible deviations of inside diameter | Permissible T deviations depending on the T/d ratio | ||||

| d | dmin | <\-0.03 | >0.03 ≤0.06 |

>0.06 ≤0.12 |

>0.12 |

| +\- 1% or +\- 2mm depending on which is greater | +2% +4mm depending on which is greater |

+\-20% | +\-15% | +\-12,5% | +\-10% |

| For the outside diameter of D≥355,6 mm, local deviation outside of the upper deviation limit by a further 5% of the wall thickness T is permitted | |||||

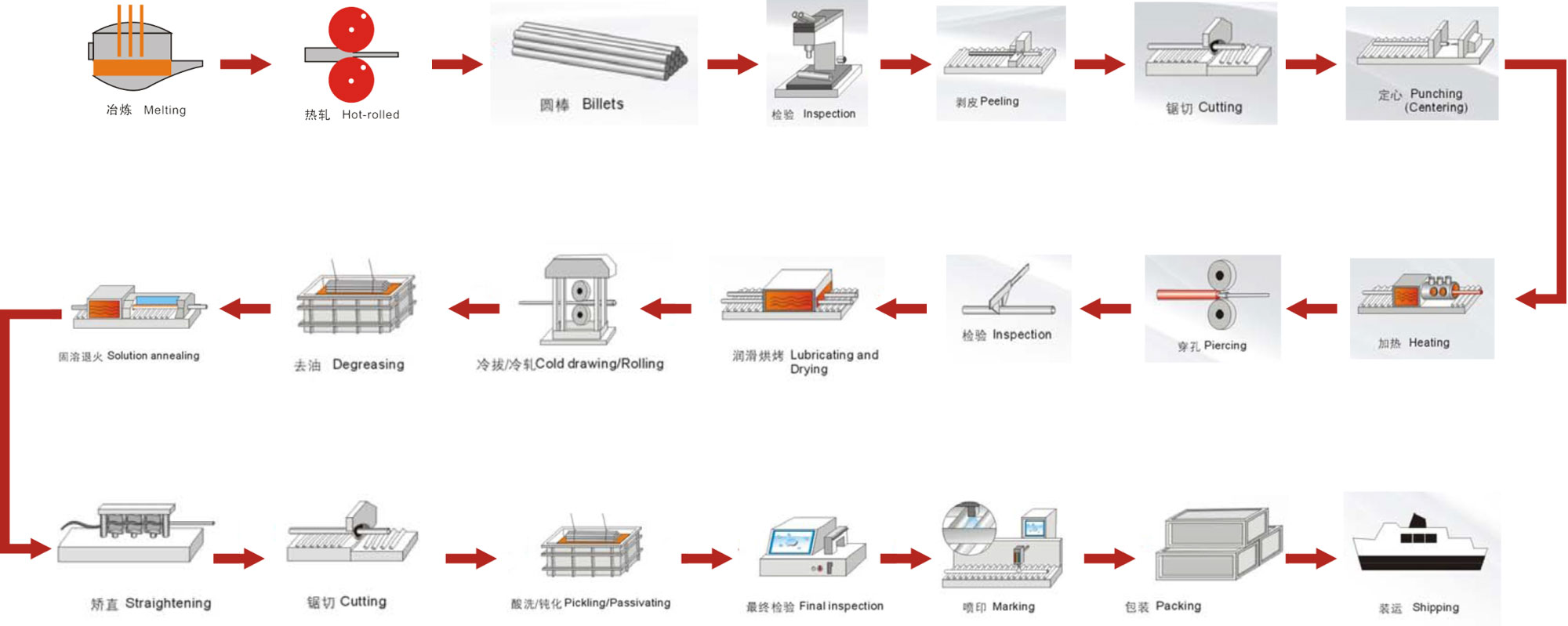

Manufacturing Process of EN 10216-2 Steel Pipe

Application of EN 10216-2 Steel Pipe

- Boiler heating surface pipe

- Economizer

- Superheater

- Reheater

- Petrochemical industry pipe

- Oil refinery piping

- Steam pipeline

- Power plant projects

- Heat-exchanger

- Heater

- Boiler

- Condenser

We are a professional Boiler And Alloy Tube manufacturer. We provide Boiler And Alloy Tube of different sizes as well as steel pipes and pipe fittings of various specifications.

Our Advantages:

1.China-leading product service provider and exporter of steel pipe

2.Competitive price and quality from our own factory

3.One-stop Resource Integration

4.Passed the ISO9001, CE, SGS certification every year

5.Best service with 24-hour response

6.Flexible payment methods

7.Strong production capacity

8.Fast delivery and standard export packaging

9.OEM/ODM

If you would like to inquire about any steel products, please feel free to contact us:sales@bestartubes.com