JIS G3454 Carbon Steel Pipe

Product description of JIS G3454 carbon steel tube

JIS G3454 carbon steel tube specification covers carbon steel pipes for pressure service. Mechanical properties of this steel grade can be varied greatly by heat treatment. Through a controlled cycle of heating and cooling, certain desired properties are obtained by producing predictable changes in the microstructure of the steel. JIS G3454 carbon steel tubes are manufactured as per JIS Specifications. JIS G3454 carbon steel tubes' mechanical properties can be varied greatly by heat treatment. JIS G3454 carbon steel tube specification covers carbon steel pipe for machine structural purposes. JIS G3454 carbon steel tubes are used for pressure conditions at a limited maximum temperature of 350℃.

Mechanical Properties of JIS G3454 Carbon Steel Tube

| Grade | Tensile Property (N/mm2) | Yield Point or Yield Strength (N/mm2) | Elongation (%) | |||

| NO. 11 Sample; NO. 12 Sample | NO. 5 Sample | NO. 4 Sample | ||||

| Longitudinal | Transverse | Longitudinal | Transverse | |||

| STPG370 | ≥ 370 | ≥ 215 | ≥ 30 | ≥ 25 | ≥ 28 | ≥ 23 |

| STPG410 | ≥ 410 | ≥ 245 | ≥ 25 | ≥ 20 | ≥ 24 | ≥ 19 |

Note:

1. For the carbon steel pipes with the thickness of less than 8 mm, we use NO.12 or NO.5 sample for tensile test. The minimum elongation will be reduced by 1.5% from the table value when the thickness reduces 1 mm. The value obtained will be rounded to an integer value according to JIS Z8401 (a rounding method).

| Grade | Sample Shape | Elongation differs according to the wall thickness. (%) | ||||||

| >7~<8 | >6~<7 | >5~<6 | >4~<5 | >3~<4 | >2~<3 | >1~<2 | ||

| STPG370 | NO.12 Sample | 30 | 28 | 27 | 26 | 24 | 22 | 21 |

| NO.5 Sample | 25 | 24 | 22 | 20 | 19 | 18 | 16 | |

| STPG410 | NO.12 Sample | 25 | 24 | 22 | 20 | 19 | 18 | 16 |

| NO.5 Sample | 20 | 18 | 17 | 16 | 14 | 12 | 11 | |

Chemical Composition of JIS G3454 Carbon Steel Tube (Unit: %)

| Grade | C | Si | Mn | P | S |

| STPG370 | ≤ 0.25 | ≤ 0.35 | 0.30-0.90 | ≤ 0.040 | ≤ 0.040 |

| STPG410 | ≤ 0.30 | ≤ 0.35 | 0.30-1.00 | ≤ 0.040 | ≤ 0.040 |

Allowable Deviation of Outer Diameter and Wall Thickness

| Type | Allowable Deviation of Outer Diameter | Allowable Deviation of Wall Thickness | ||

| Hot-Working Seamless Steel Tube | ≤ 40A | ± 0.5 mm | < 4 mm | ﹢0.6mm 0.5 |

| ≥ 30A ≤ 125A | ± 1% | |||

| 150A | ± 1.6 mm | |||

| ≥ 200A | ± 0.8% | ≥ 4mm | ﹢15% ﹣12.5% | |

| For ≥350A ones, we can measure according to the perimeter. The allowable deviation is ± 0.5%. | ||||

| Cold-Working Seamless Steel Pipe and Electric-Resistance Welded Steel Pipe | ≤ 25A | ± 0.03 mm | < 3 mm ≥ 3 mm | ± 0.3 mm ± 10% |

| ≥ 32A | ± 0.8% | |||

| For ≥350A ones, we can measure according to the perimeter. The allowable deviation is ± 0.5%. | ||||

Note:

1. When we measure the outer diameter through perimeter, we can determine by converting circumference measurement or measured value to be the outer diameter. Both are applicable to the same tolerance (± 0.5%).

2. For the repaired parts, confirm the wall thickness tolerance meets the above table. The outer diameter tolerance is not applicable to the table.

3. The appearance of carbon steel pipes used below 350℃ is regulated by the following provisions:

1) The carbon steel tube should be straight with practicality. Its ends must be perpendicular to the tube axis.

2) The inner and outer of tube should be processed well without harmful defects.

4. Size and Weight of Carbon Steel Pipe

JIS Pipe dimension

| Nominal size | Outside

diameter (mm) |

Carbon steel

pipes for ordinary piping <SGP> (JIS G3452) |

Carbon steel pipes for pressure service

<STPG>(JIS G3454) |

||||||

| Nominal thickness | |||||||||

| A | B | Thickness (mm) | Sch10 | Sch20 | Sch30 | Sch40 | Sch60 | Sch80 | |

| 6 | 1/8 | 10.5 | 2.0 | – | – | – | 1.7 | 2.2 | 2.4 |

| 8 | 1/4 | 13.8 | 2.3 | – | – | – | 2.2 | 2.4 | 3.0 |

| 10 | 3/8 | 17.3 | 2.3 | – | – | – | 2.3 | 2.8 | 3.2 |

| 15 | 1/2 | 21.7 | 2.8 | – | – | – | 2.8 | 3.2 | 3.7 |

| 20 | 3/4 | 27.2 | 2.8 | – | – | – | 2.9 | 3.4 | 3.9 |

| 25 | 1 | 34.0 | 3.2 | – | – | – | 3.4 | 3.9 | 4.5 |

| 32 | 1.1/4 | 42.7 | 3.5 | – | – | – | 3.6 | 4.5 | 4.9 |

| 40 | 1.1/2 | 48.6 | 3.5 | – | – | – | 3.7 | 4.5 | 5.1 |

| 50 | 2 | 60.5 | 3.8 | – | 3.2 | – | 3.9 | 4.9 | 5.5 |

| 65 | 2.1/2 | 76.3 | 4.2 | – | 4.5 | – | 5.2 | 6.0 | 7.0 |

| 80 | 3 | 89.1 | 4.2 | – | 4.5 | – | 5.5 | 6.6 | 7.6 |

| 90 | 3.1/2 | 101.6 | 4.2 | – | 4.5 | – | 5.7 | 7.0 | 8.1 |

| 100 | 4 | 114.3 | 4.5 | – | 4.9 | – | 6.0 | 7.1 | 8.6 |

| 125 | 5 | 139.8 | 4.5 | – | 5.1 | – | 6.6 | 8.1 | 9.5 |

| 150 | 6 | 165.2 | 5.0 | – | 5.5 | – | 7.1 | 9.3 | 11.0 |

| 200 | 8 | 216.3 | 5.8 | – | 6.4 | 7.0 | 8.2 | 10.3 | 12.7 |

| 250 | 10 | 267.4 | 6.6 | – | 6.4 | 7.8 | 9.3 | 12.7 | 15.1 |

| 300 | 12 | 318.5 | 6.9 | – | 6.4 | 8.4 | 10.3 | 14.3 | 17.4 |

| 350 | 14 | 355.6 | 7.9 | 6.4 | 7.9 | 9.5 | 11.1 | 15.1 | 19.0 |

| 400 | 16 | 406.4 | 7.9 | 6.4 | 7.9 | 9.5 | 12.7 | 16.7 | 21.4 |

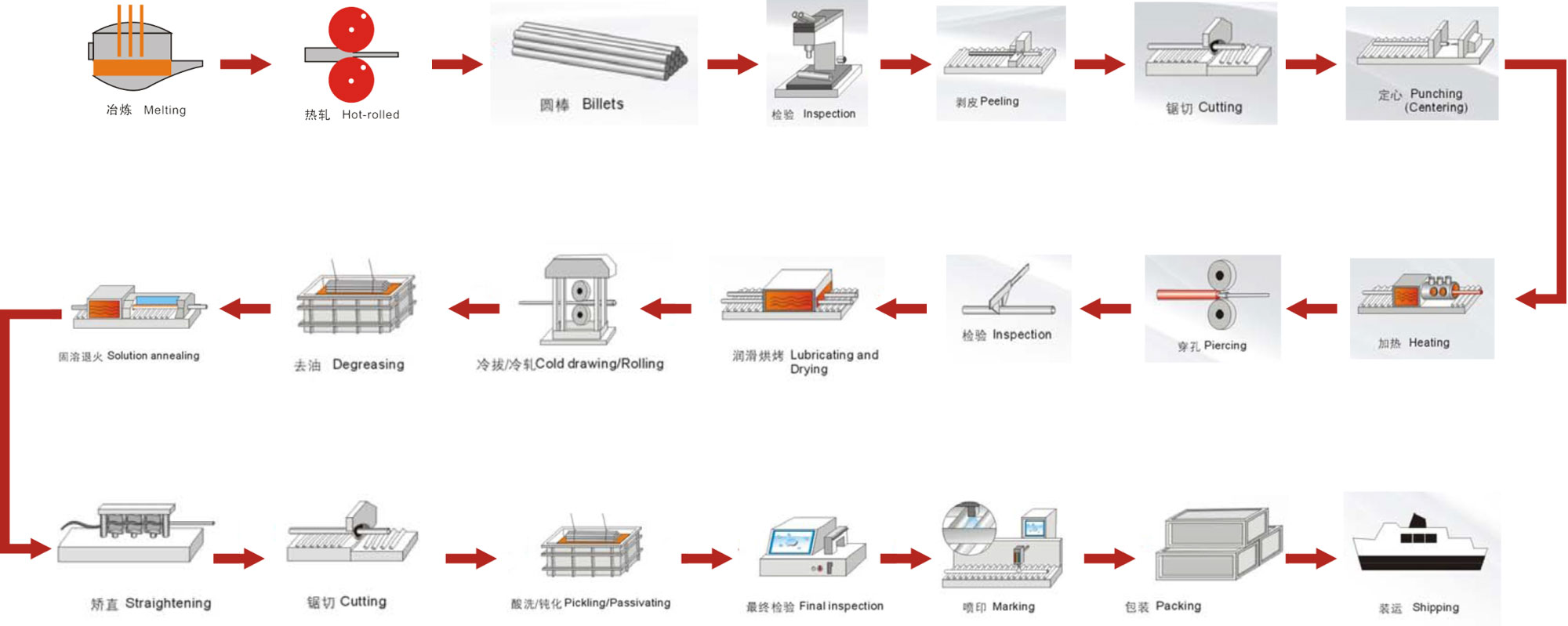

Manufacturing Process of JIS G3454 Carbon Steel Tubes

Application of JIS G3454 carbon steel tube

- Automobile sectors

- Interior & exterior architectural structures

- Water pipelines

- Gas lines

- Oil & Gas industries

- Pressure service

- Boiler & electric power

- Machinery

- Gas tank

- Chemical engineering

- Offshore and petroleum engineering