News

-

Things to note when installing stainless steel pipe fittings

The use of flat joints for stainless steel pipe fittings requires high pipe quality, as well as the outer diameter ovality, wall thickness, and physical properties of the rubber ring of cast iron drainage pipes. Since the flat joints have poor watertight performance conditions...Read more -

The difference between fixed length and indefinite length of Q235A spiral steel pipe

The length of steel pipes for pipelines, but for the convenience of users, when the steel pipes are sold at any time, the Q235A spiral steel pipes are produced with variable length pipes within the standards, but when the actual order is made, the standard length steel pipes a...Read more -

Precautions for using stainless steel flanges

Although stainless steel flanges have unique advantages in terms of material, no matter how good they are, they still need to be used with caution, so that they can be used for a longer period. So what should you know about the specific use of stainless steel flanges? 1. To pr...Read more -

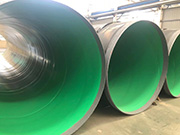

The scope of application of epoxy resin coated steel pipes

Epoxy resin-coated steel pipe coating is a thermosetting plastic that combines the common advantages of steel and plastic. Its scope of application includes 1. Fire sprinkler system and domestic water supply and drainage; 2. Gas drainage, mud transportation, and ventilation sy...Read more -

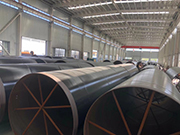

Which is better, spiral welded steel pipe or welded steel pipe

1. The materials are the same but the uses are different, so there is no question of who is better. 2. Spiral welded steel pipe refers to a steel pipe with seams on the surface, which is made by bending and deforming steel strips or steel plates into circular, square, and othe...Read more -

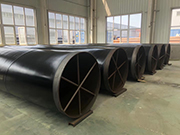

What are the insulation methods for anti-corrosion steel pipes

Anti-corrosion steel pipe is a common steel pipe. To slow down and prevent the steel pipe from corroding and depreciating under the chemical and electrochemical effects of internal and external media, or due to the metabolism of microorganisms, it is necessary to do a good job...Read more -

Performance comparison between spiral steel pipe and straight seam steel pipe

1. Welding process: In terms of the welding process, the welding methods of spiral steel pipes and straight seam welded pipes are the same, but straight seam welded pipes inevitably have many T-shaped welds, so the probability of welding defects is greatly increased, and the w...Read more -

Three common connection methods for 3PE anti-corrosion steel pipes

(1) Welding connection: If there is no need to disassemble, you can choose welding. This is a more traditional connection method. It has a simple structure and can directly connect components of any form. It is economical to use materials and does not weaken the cross-section....Read more -

The difference between cold-drawn steel pipe and hot-rolled steel pipe

The difference between hot processing and cold processing is: that hot rolling is hot processing, and cold drawing is cold processing. The main difference is: that hot rolling is rolling above the recrystallization temperature, cold rolling is rolling below the recrystallizati...Read more