Berita

-

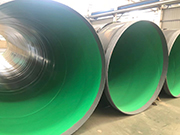

Proses pengeluaran paip keluli bersalut resin epoksi di dalam dan di luar

Mula-mula, pra-rawat paip asas paip keluli bersalut resin epoksi di dalam dan di luar—-mengisar paip keluli (Kelebihan: Penyemburan automatik menjadikan salutan dinding dalam dan luar substrat seragam dan mempunyai perataan yang baik. Memenuhi standard CJ/T120-2008 dan GB/T5135...Baca lagi -

Paip keluli tergalvani adalah bahan tahan kakisan yang digunakan secara meluas

Paip keluli tergalvani adalah produk keluli biasa yang digunakan secara meluas dalam pembinaan, pembuatan, dan bidang perindustrian. Ia memberikan rintangan kakisan dan kekuatan mekanikal yang sangat baik dengan menyalut lapisan zink pada permukaan paip keluli, jadi ia sangat popular. Pertama,...Baca lagi -

Sifat mekanikal kekuatan mampatan paip keluli Q235

Pertama, apakah paip keluli Q235? Paip keluli Q235 ialah paip keluli struktur karbon biasa, digunakan secara meluas dalam pembinaan, jambatan, pembuatan jentera, dan bidang lain. Ia mempunyai keplastikan dan prestasi kimpalan yang baik, dan harganya agak rendah, jadi ia telah digunakan secara meluas...Baca lagi -

Apakah nilai yang ditentukan untuk ketebalan dinding paip keluli

Paip keluli merupakan bahan binaan yang penting dan digunakan secara meluas dalam pelbagai bidang. Ketebalan dinding paip keluli adalah salah satu parameter pentingnya, yang berkaitan secara langsung dengan kekuatan, kapasiti galas beban, dan hayat perkhidmatan paip keluli. Jadi, apakah spesis...Baca lagi -

Ketebalan dinding dan rintangan tekanan paip keluli tahan karat

1. Ketebalan dinding paip keluli tahan karat mempunyai pengaruh penting pada rintangan tekanannya Dalam industri keluli, paip keluli tahan karat adalah bahan biasa dan digunakan secara meluas dalam pembinaan, industri kimia, peralatan perubatan, dan bidang lain. Tebal dinding...Baca lagi -

Penyelesaian tompok karat pada siku keluli tahan karat

Tompok karat muncul pada siku keluli tahan karat, menunjukkan bahawa siku tidak diperbuat daripada keluli tahan karat tulen, tetapi adalah siku keluli tahan karat bersaduran elektrik. Tompok karat boleh digilap dengan kertas pasir ultra halus dan kemudian disembur dengan varnis tidak berwarna untuk pencegahan karat sebelum...Baca lagi -

Ciri-ciri geometri bahagian paip keluli berdiameter besar

(1) Sambungan nodnya sesuai untuk kimpalan langsung, tanpa plat nod atau penyambung lain, yang menjimatkan tenaga kerja dan bahan. (2) Apabila perlu, konkrit boleh dituang di dalam paip untuk membentuk komponen komposit. (3) Ciri-ciri geometri keratan paip...Baca lagi -

Ciri-ciri paip skrin minyak

1. Paip skrin minyak diproses oleh badan sarung minyak J55 atau N80, dengan kekuatan tinggi dan tidak mudah berubah bentuk. 3. Kawasan aliran adalah besar. Paip skrin 27/8″ mempunyai ...Baca lagi -

Perbezaan antara tiub keluli lingkaran berdinding nipis dan tiub keluli lingkaran berdinding tebal

Pertama, konsep tiub keluli lingkaran berdinding nipis: keluli jalur dimasukkan ke dalam unit paip yang dikimpal, dan selepas bergolek berbilang roller, keluli jalur digulung secara beransur-ansur untuk membentuk tiub bulat kosong dengan jurang terbuka. Jumlah menekan penggelek penyemperitan dilaraskan...Baca lagi