News

-

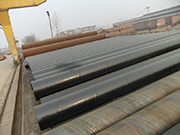

Causes of rust and corrosion of spiral steel pipe

Because spiral steel pipes are stacked outdoors, and most of them are buried in the ground when they are in use, they are easy to corrode and rust. To ensure the smooth flow of the pipes, spiral steel pipe manufacturers must have strong corrosion resistance. Once the pipeline ...Read more -

What inspections do submerged arc steel pipes need to go through after production

In the process of producing submerged arc steel pipes, the temperature must be strictly controlled, to ensure the reliability of welding. If the temperature is too low, it may cause the welding position to fail to reach the temperature required for welding. When most of the me...Read more -

How to avoid rusting of precision stainless steel pipe fittings

1. Do not contact other metals, because stainless steel pipe fittings will be rusted by the attachment of dissimilar metals, such as screws, etc. Although it is not serious at the beginning, if you wipe it with a cloth and a neutral detergent, you will see rust. 2. Another fac...Read more -

The difference between thin-walled spiral steel pipe and thick-walled spiral steel pipe

The concept of thin-walled spiral steel pipe: the strip steel is fed into the welded pipe unit, rolled by multiple rollers, the strip steel is gradually rolled up to form a circular tube billet with an opening gap, and the reduced amount of the extrusion roller is adjusted to ...Read more -

Eddy’s current non-destructive testing method for a weld seam of spiral welded pipe

Pipeline transportation, as an efficient means of special transportation, has played an increasingly important role in oil and gas transportation and other fields. At present, domestic large-diameter transportation pipelines are mainly constructed of spiral welded steel pipes....Read more -

Large-diameter welded pipe production process

Large-diameter welded pipe production process 1: Conduct physical and chemical inspections of raw materials such as strip steel coils, welding wires, and fluxes. 2: The head-to-tail butt joint of the strip steel adopts single-wire or double-wire submerged arc welding, and auto...Read more -

Description of the length and mechanical properties of large-diameter steel pipes

The main processing methods of large-diameter steel pipes are: forging steel: a pressure processing method that uses the reciprocating impact force of a forging hammer or the pressure of a press to change the blank into the shape and size we need. Extrusion: It is a processing...Read more -

Selection of anti-corrosion coatings for steel pipes

There are many kinds of steel pipe anti-corrosion coatings, and their properties and uses are different. The correct selection is very important for the anti-corrosion effect and service life of the coating. When choosing, you should consider: 1. The properties of the surface ...Read more -

The difference between submerged arc welded spiral steel pipe and straight seam high frequency welded steel pipe

The submerged arc welding spiral steel pipe uses continuous welding wire as the electrode and filler metal. During work, a layer of granular flux is covered in the welding area. The arc of the large-diameter spiral pipe burns under the flux layer to melt the end of the welding...Read more