News

-

Technical characteristics of spiral steel pipe

Spiral steel pipes are mainly used in tap water engineering, the petrochemical industry, the chemical industry, the electric power industry, agricultural irrigation, and urban construction, and are twenty key products developed. For liquid transportation: water supply, drainag...Read more -

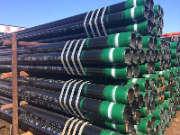

The use of OCTG casing

The OCTG casing is a large-diameter pipe that acts to fix the wall or bore of oil and gas oil wells. The casing is inserted into the wellbore and fixed with cement to help the wellbore separate the rock formations and prevent the wellbore from collapsing while ensuring the cir...Read more -

The reasons for the leakage of hot-dip galvanizing of seamless steel pipes

The leakage of hot-dip galvanizing of seamless steel pipes causes and solutions: 1. The surface of the plated parts is not clean (1) The surface of the plated parts contains paint, grease, and soldering iron; it can be polished or scrubbed with relevant solvents. ⑵ iron oxide;...Read more -

What happens to the stainless steel pipe after pickling

With the wide application of stainless steel pipes, people’s requirements for them are getting higher and higher, and the processing technology has also become diversified. Pickling is one of the processing techniques. Do you know why hydrogen embrittlement occurs in sta...Read more -

Definition of oil casing

The special oil casing is mainly used for the drilling of oil and gas wells and the transportation of oil and gas. It includes oil drilling pipes, oil casings, and oil-sucking pipes. Oil drill pipes are mainly used to connect drill collars and drill bits and transmit drilling ...Read more -

Manufacturing Technology of Large Diameter Longitudinal Submerged Arc Welded Steel Pipe

The large-diameter straight seam submerged arc steel pipe is mainly responsible for the pipeline transportation of marine and land oil and gas, oil and natural gas, coal and mineral paddles, etc. It is especially suitable for the “West-East Gas Pipeline” project cu...Read more -

The purpose of preheating the pipe before welding the spiral steel pipe

The purpose of preheating the spiral steel pipe before welding is as follows: (1) Preheating can slow down the cooling rate after welding so that hydrogen diffuses in the weld metal and escapes to avoid cracking caused by hydrogen. It can also reduce the degree of hardening of...Read more -

Anti-corrosion Countermeasures for Oil Casing

1. First of all, do a good job of water quality standards, and strictly monitor and manage water quality. Implement cleaning and separate injection, strengthen the cleaning of the main water pipeline, ensure that the water quality in the station and the bottom of the well meet...Read more -

How to improve the stability of spiral seam submerged arc welded steel pipe in the warehouse

With spiral seam submerged arc welded steel pipe in the warehouse, the spiral steel pipe quality become a problem for us. How improve the stability of spiral seam submerged arc welded steel pipe in the warehouse become more and more important. 1) Dimensions of steel wire, reba...Read more