Product Information

-

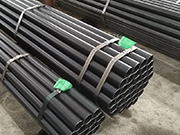

GCr15 precision steel pipe details from material to application

GCr15 precision steel pipe, as an important special steel, plays a vital role in the industrial field. First, the material composition of GCr15 precision steel pipe The main material of GCr15 precision steel pipe is GCr15 steel, which is a kind of alloy structural steel. Its m...Read more -

Application and characteristics of the industrial DN450 seamless steel pipe

DN450 seamless steel pipe is a common pipe in the steel industry, with a wide range of applications and unique characteristics. First, the application scope of DN450 seamless steel pipe DN450 seamless steel pipe, as a commonly used pipe, has been widely used in many fields 1. ...Read more -

Galvanized steel pipe SC15 is an important choice for anti-corrosion engineering construction

Galvanized steel pipe SC15, as a commonly used building material, is highly favored for its anti-corrosion performance and wide applicability. In engineering construction, it is crucial to choose the right galvanized steel pipe SC15. 1. Characteristics of galvanized steel pipe...Read more -

Deciphering the characteristics of steel pipe 1213

Steel pipe 1213, as a common steel pipe material, has many unique properties that make it widely used in various applications. Let’s take a deep look at these properties to better understand their application in the industrial and construction fields. 1. Chemical composi...Read more -

Understand the size, material, and application field of DN80 steel pipe

DN80 steel pipe is a common pipe size, which plays an important role in the steel industry. First, the size specifications of DN80 steel pipe The size specifications of DN80 steel pipe are defined according to the international standard ISO6708, which refers to the nominal dia...Read more -

Explore the manufacturing process and application fields of DN2008 seamless steel pipe

DN2008 seamless steel pipe is a key pipe that plays an important role in the industrial and construction fields. Understanding its manufacturing process and application fields can help us better understand the characteristics and advantages of this type of steel pipe. 1. Manuf...Read more -

Application and performance analysis of 15CrMoG alloy steel pipe

15CrMoG alloy steel pipe is a common alloy steel pipe material with a wide range of applications and important economic value. 15CrMoG steel pipe is an alloy structural steel pipe, mainly composed of 15CrMoG alloy elements, with excellent high-temperature strength and oxidatio...Read more -

What are the heat treatment methods for stainless steel

1. Ferritic stainless steel: The main alloying element is Cr, or a small number of stable ferrite elements such as Al, Mo, etc. are added, and the structure is ferrite. The strength is not high, and the performance cannot be adjusted by heat treatment methods. It has a certain...Read more -

How to distinguish 304 stainless steel from 316 stainless steel

Generally speaking, the most common types of stainless steel are 304 stainless steel and 316 stainless steel, but what is the difference between the two? The first thing to talk about is the issue of food grade. In life, we often encounter people who buy stainless steel items,...Read more