OCTG Casing

What is OCTG Casing?

OCTG casing is used for lining the borehole which has been dug into the ground for procuring oil or gas and stabilizing it. An OCTG casing is subject to axial tensions and high internal pressures which are generated while pumping oil or gas. Similar to the drill pipe, the oil well OCTG casing is also subjected to axial tension, therefore they are required to be made from high-quality strong steel material. They also have to bear the external pressures arising from the surrounding rocks underground.

OCTG casing is a large diameter pipe that needs to be cemented into the borehole. The diameters of OCTG casing range from 4.5″ to 20″. Bestar Steel has much experience in supplying OCTG casing, which will be the best rate and internationally certificated quality. OCTG casing is a large diameter pipe that is held in place in the borehole using cement. The pipe is well-cemented and stands strong, it acts as the structural component of the well and offers hole integrity. The OCTG casing prevents the well from collapsing when the drilling process is on. Well-cemented casing should last the life of the well.

Mechanical Properties of OCTG Casing

|

Group |

Grade |

Type |

Total elongation under load % |

Yield strength Mpa |

Tensile strength min MPa |

Hardness max |

||

|

min |

max |

HRC |

HBW |

|||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

1 |

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

|

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

|

|

N80 |

1 |

0.5 |

552 |

758 |

689 |

- |

- |

|

|

N80 |

Q |

0.5 |

552 |

758 |

689 |

- |

- |

|

|

2 |

L80 |

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

L80 |

9Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

|

L80 |

13Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

|

C90 |

|

0.5 |

621 |

724 |

689 |

25.4 |

255 |

|

|

C95 |

- |

0.5 |

655 |

758 |

724 |

- |

- |

|

|

T95 |

|

0.5 |

655 |

758 |

724 |

25.4 |

255 |

|

|

3 |

P110 |

- |

0.6 |

758 |

965 |

862 |

- |

- |

|

4 |

Q125 |

All |

0.65 |

862 |

1034 |

931 |

- |

-

|

Chemical Composition of OCTG Casing

| Chemical Composition of OCTG Casing | |||||||||||

| Standard | Grade | Chemical compositions(%) | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34~0.39 | 0.20~0.35 | 1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34~0.38 | 0.20~0.35 | 1.45~1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11~0.16 | |

| L80 | 0.15~0.22 | ≤1.00 | 0.25~1.00 | ≤0.020 | ≤0.010 | 12.0~14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26~0.395 | 0.17~0.37 | 0.40~0.70 | ≤0.020 | ≤0.010 | 0.80~1.10 | ≤0.20 | ≤0.20 | 0.15~0.25 | ≤0.08 | |

Connections of OCTG Casing

- short round thread casing (STC);

- long round thread casing (LC);

- buttress thread casing (BC);

- extreme-line casing (XC);

- non-upset tubing (NU);

- external upset tubing (EU);

- integral joint tubing (IJ).

Production Process of OCTG Casing

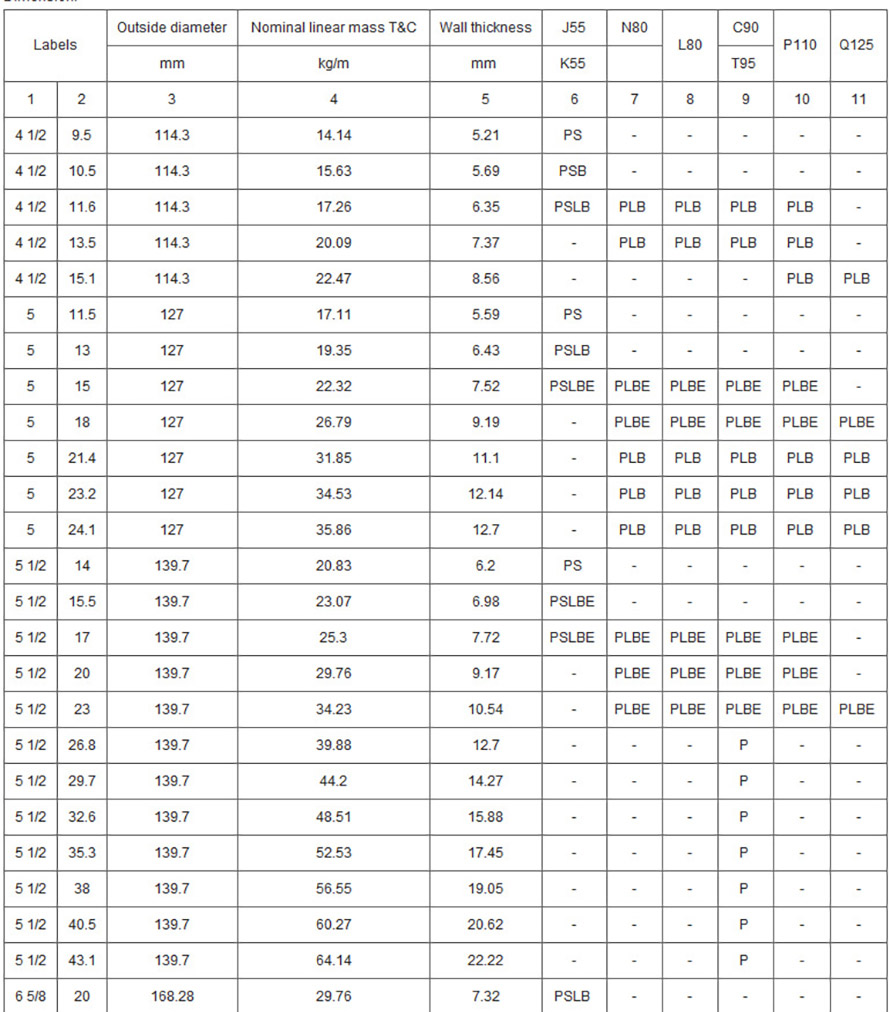

Size Chart of OCTG Casing

Application of OCTG Casing

1. Holds on to the drill string, preventing the unsteady upper formation of the well from caving in.

2. Prevents contamination

3. Offers an internal bore which facilitates easy installation of the production equipment.

4. Prevents any form of fluid (oil) loss.

5. To help seal off the high-pressure zones from the surface of the earth.

The different types of casings are conductor casing, surface casing, intermediate casing, production casing, liner, and liner tieback casing.

We are a professional OCTG Casing manufacturer. We provide OCTG Casing of different sizes as well as steel pipes and pipe fittings of various specifications.

Our Advantages:

1.China-leading product service provider and exporter of steel pipe

2.Competitive price and quality from our own factory

3.One-stop Resource Integration

4.Passed the ISO9001, CE, SGS certification every year

5.Best service with 24-hour response

6.Flexible payment methods

7.Strong production capacity

8.Fast delivery and standard export packaging

9.OEM/ODM

If you would like to inquire about any steel products, please feel free to contact us:sales@bestartubes.com