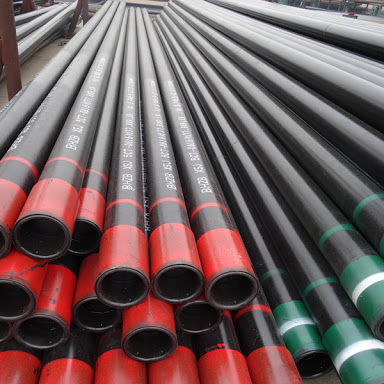

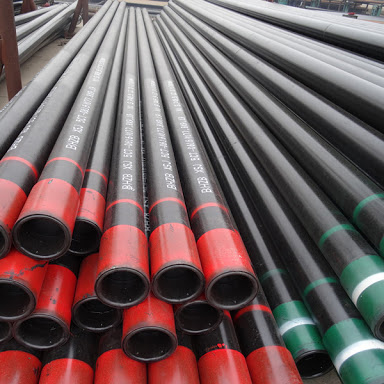

OCTG Tubing

What is OCTG Tubing?

An OCTG tubing is a pipe that is placed inside the wellbore through the casing pipe. It is responsible for the transportation of the hydrocarbons to the surface. It is an oil well tubing either used for transporting natural gas or crude oil to the facilities for further processing after the drilling is complete. Similar to the drill pipe and casing, tubing also is subjected to high pressure during the extraction process and hence needs to be thick, strong, and sturdy. An OCTG tubing is used for transporting natural gas or crude oil after the drilling is complete. It transports the gas and oil to the facilities for further processing. Similar to the drill pipe and casing, OCTG tubing also has to withstand high pressure during the extraction process, and hence they are required to meet industry standards. OCTG tubings are available in various sizes ranging from 1 1/4” to 4.5”.

The tubing protects the casing from wear and tear caused by corrosive fluids, sand, paraffin, and more. In case of damage or breakage, the OCTG tubing can be easily replaced.

Dimension of OCTG Tubing

|

Group |

Grade |

Type |

Total elongation under load % |

Yield strength Mpa |

Tensile strength min MPa |

Hardness max |

||

|

min |

max |

HRC |

HBW |

|||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

1 |

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

|

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

|

|

N80 |

1 |

0.5 |

552 |

758 |

689 |

- |

- |

|

|

N80 |

Q |

0.5 |

552 |

758 |

689 |

- |

- |

|

|

2 |

L80 |

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

L80 |

9Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

|

L80 |

13Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

|

C90 |

|

0.5 |

621 |

724 |

689 |

25.4 |

255 |

|

|

C95 |

- |

0.5 |

655 |

758 |

724 |

- |

- |

|

|

T95 |

|

0.5 |

655 |

758 |

724 |

25.4 |

255 |

|

|

3 |

P110 |

- |

0.6 |

758 |

965 |

862 |

- |

- |

|

4 |

Q125 |

All |

0.65 |

862 |

1034 |

931 |

- |

-

|

Mechanical Properties of OCTG Tubing

| Label | D Outside diameter mm | Wall thickness t mm | C Type of end-finish | |||||||||

| 1 | 2 | H40 | J55 | L80 | N80 1Q | C90 | T95 | P110 | ||||

| NU T&C | EU T&C | IJ | ||||||||||

| 1 | 2 | 3 | 4 | 5 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.9 | 2.75 | 2.9 | 2.76 | 48.26 | 3.68 | PNUI | PNUI | PNUI | PNUI | PNUI | PNUI | - |

| 1.9 | 3.65 | 3.73 | - | 48.26 | 5.08 | PU | PU | PU | PU | PU | PU | PU |

| 1.9 | 4.42 | - | - | 48.26 | 6.35 | - | - | P | - | P | P | - |

| 2.375 | 4 | - | - | 60.32 | 4.24 | PU | PN | PN | PN | PN | PN | - |

| 2.375 | 4.6 | 4.7 | - | 60.32 | 4.83 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 2.375 | 5.8 | 5.95 | - | 60.32 | 6.45 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2.375 | 6.6 | - | - | 60.32 | 7.49 | - | - | P | - | P | P | - |

| 2.375 | 7.35 | 7.45 | - | 60.32 | 8.53 | - | - | PU | - | PU | PU | - |

| 2.875 | 6.4 | 6.5 | - | 73.02 | 5.51 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 2.875 | 7.8 | 7.9 | - | 73.02 | 7.01 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2.875 | 8.6 | 8.7 | - | 73.02 | 7.82 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2.875 | 9.35 | 9.45 | - | 73.02 | 8.64 | - | - | PU | - | PU | PU | - |

| 2.875 | 10.5 | - | - | 73.02 | 9.96 | - | - | P | - | P | P | - |

| 3.5 | 7.7 | - | - | 88.9 | 5.49 | PN | PN | PN | PN | PN | PN | - |

| 3.5 | 9.2 | 9.3 | - | 88.9 | 6.45 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 3.5 | 10.2 | - | - | 88.9 | 7.34 | PN | PN | PN | PN | PN | PN | - |

| 3.5 | 12.7 | 12.95 | - | 88.9 | 9.52 | - | - | PNU | PNU | PNU | PNU | PNU |

| 3.5 | 14.3 | - | - | 88.9 | 10.92 | - | - | P | - | P | P | - |

| 3.5 | 15.5 | - | - | 88.9 | 12.09 | - | - | P | - | P | P | - |

| 4 | 9.5 | - | - | 101.6 | 5.74 | PN | PN | PN | PN | PN | PN | - |

| 4 | 10.7 | 11 | - | 101.6 | 6.65 | PU | PU | PU | PU | PU | PU | - |

| 4 | 13.2 | - | - | 101.6 | 8.38 | - | - | P | - | P | P | - |

| 4 | 16.1 | - | - | 101.6 | 10.54 | - | - | P | - | P | P | - |

| 4.5 | 12.6 | 12.75 | - | 114.3 | 6.88 | PNU | PNU | PNU | PNU | PNU | PNU | - |

| 4.5 | 15.2 | - | - | 114.3 | 8.56 | - | - | P | - | P | P | - |

Production Process of OCTG Tubing

Connection of OCTG Tubing

OCTG tubing is applicable to the following connections which comply with API SPEC:

• SC: Short round thread casing

• LC: Long round thread casing

• BC: Buttress thread casing

• NU: Non-upset tubing

• EU: External upset tubing

• IJ: Integral tubing connections

Size Chart of OCTG Tubing

| Label | OD (mm) | WT (mm) | Type of End-finish | |||||||||

| NU T&C | EU T&C | IJ | H40 | J55 | L80 | N80 | C90 | T95 | P110 | |||

| 1.9 | 2.75 | 2.9 | 2.76 | 48.26 | 3.68 | PNUI | PNUI | PNUI | PNUI | PNUI | PNUI | - |

| 1.9 | 3.65 | 3.73 | - | 48.26 | 5.08 | PU | PU | PU | PU | PU | PU | PU |

| 1.9 | 4.42 | - | - | 48.26 | 6.35 | - | - | P | - | P | P | - |

| 2 3/8 | 4 | - | - | 60.32 | 4.24 | PU | PN | PN | PN | PN | PN | - |

| 2 3/8 | 4.6 | 4.7 | - | 60.32 | 4.83 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 2 3/8 | 5.8 | 5.95 | - | 60.32 | 6.45 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 3/8 | 6.6 | - | - | 60.32 | 7.49 | - | - | P | - | P | P | - |

| 2 3/8 | 7.35 | 7.45 | - | 60.32 | 8.53 | - | - | PU | - | PU | PU | - |

| 2 7/8 | 6.4 | 6.5 | - | 73.02 | 5.51 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 | 7.8 | 7.9 | - | 73.02 | 7.01 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 | 8.6 | 8.7 | - | 73.02 | 7.82 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 | 9.35 | 9.45 | - | 73.02 | 8.64 | - | - | PU | - | PU | PU | - |

| 2 7/8 | 10.5 | - | - | 73.02 | 9.96 | - | - | P | - | P | P | - |

| 3 1/2 | 7.7 | - | - | 88.9 | 5.49 | PN | PN | PN | PN | PN | PN | - |

| 3 1/2 | 9.2 | 9.3 | - | 88.9 | 6.45 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 3 1/2 | 10.2 | - | - | 88.9 | 7.34 | PN | PN | PN | PN | PN | PN | - |

| 3 1/2 | 12.7 | 12.95 | - | 88.9 | 9.52 | - | - | PNU | PNU | PNU | PNU | PNU |

| 3 1/2 | 14.3 | - | - | 88.9 | 10.92 | - | - | P | - | P | P | - |

| 3 1/2 | 15.5 | - | - | 88.9 | 12.09 | - | - | P | - | P | P | - |

| 4 | 9.5 | - | - | 101.6 | 5.74 | PN | PN | PN | PN | PN | PN | - |

| 4 | 10.7 | 11 | - | 101.6 | 6.65 | PU | PU | PU | PU | PU | PU | - |

| 4 | 13.2 | - | - | 101.6 | 8.38 | - | - | P | - | P | P | - |

| 4 | 16.1 | - | - | 101.6 | 10.54 | - | - | P | - | P | P | - |

| 4 1/2 | 12.6 | 12.75 | - | 114.3 | 6.88 | PNU | PNU | PNU | PNU | PNU | PNU | - |

| 4 1/2 | 15.2 | - | - | 114.3 | 8.56 | - | - | P | - | P | P | - |

Application of OCTG Tubing According to the API 5CT standard, the steel material used for making the pipe billet supplied shall be grain refining treatment. This steel shall contain one or more grain refining elements, such as a certain amount of aluminum, niobium, vanadium, or titanium so that the austenite grains of the steel Grain refinement. • Pipes supplied shall be manufactured in seamless type or EW type. • Couplings, coupling stock, and coupling materials shall be seamless. • Cold-drawn tubing pipe shall be properly heat treated, otherwise is not acceptable. • Casing and tubing attachment materials shall be seamless pipe unless other type stated on the order. API 5CT is standard technical specifications for steel casing and tubing pipes used for oil wells in petroleum and natural gas industries. Besides casing and tubing, it also includes pup joints, coupling stock, coupling material, and accessory materials, and establishes requirements for three product specification levels (PSL-1, PSL-2, and PSL-3). The requirements for PSL-1 are the basis of this standard.

We are a professional OCTG Tubing manufacturer. We provide OCTG Tubing of different sizes as well as steel pipes and pipe fittings of various specifications.

Our Advantages:

1.China-leading product service provider and exporter of steel pipe

2.Competitive price and quality from our own factory

3.One-stop Resource Integration

4.Passed the ISO9001, CE, SGS certification every year

5.Best service with 24-hour response

6.Flexible payment methods

7.Strong production capacity

8.Fast delivery and standard export packaging

9.OEM/ODM

If you would like to inquire about any steel products, please feel free to contact us:sales@bestartubes.com